We put more engineering into what we design, aiming for quality, reliability, and longevity

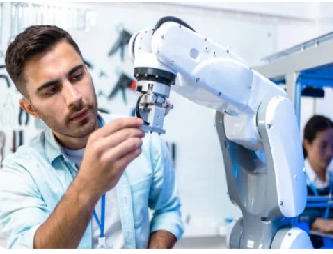

KTM Research is a custom integration services company building systems, tools, and machines to support our clients in optimizing their operations, enhancing productivity, and solving complex manufacturing and production challenges.

Specializing in industrial machine vision, vision-guided robotics, and automation, KTM Research serves industries ranging from consumer electronics to apparel manufacturers.

ENGINEERING SERVICES

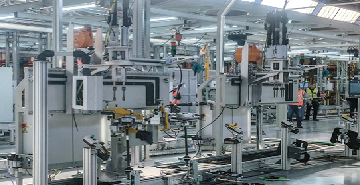

Turnkey Automation

We offer turnkey solutions specializing in system integration, machine design, electronic controls, software development, and final assembly.

Machine Vision

Comprehensive experience with complex machine vision applications for vision-guided robotics and quality control.

System Controls

Extensive experience developing custom control solutions, from full system integration to upgrading existing systems while minimizing downtime.

Have questions or need a custom solution?

Contact us today and let our experts help bring your vision to life!

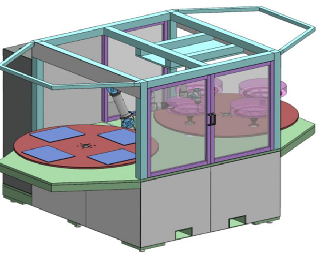

SPM TECHNOLOGIES

KTM Research knows that innovative projects can take on many forms. We specialize in designing and building custom Special Purpose Machines (SPMs) tailored to unique operational needs. From concept to deployment, we are ready to work with you to deliver precision-engineered solutions that optimize processes, enhance efficiency, and ensure superior performance.

Machine Vision Tools

KTM Research’s core competency lies in using machine vision and deep learning software to analyze images, enabling the identification, classification, and quantification of key characteristics to sort objects, make automated quality decisions, and control robotic actions. We have experience with most major vision software systems, including MVTec Halcon, Cognex Vision Pro, Cognex Insight, Keyence, Sick, Teledyne Dalsa and LMI Gocater. KTM has extensive experience with Halcon and Vision Pro, and has successfully delivered multiple systems to customers in the US and Asia that implement complex quality control decisions, robot pick-and-place processes, and object classification and sorting of product types.

Turnkey Integration

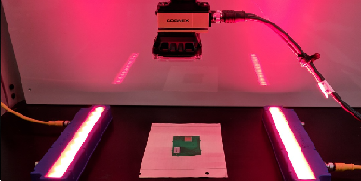

Inspect physical defects such as scratches, dents, puncture holes with high-speed vision cameras. This example applies special lighting and computer filter techniques to make details and defects that would normally be difficult to inspect clear and easy to see.

Reveal Hidden Details

Successfully extract physical features regardless of glare. The shiny surface would normally make this inspection extremely difficult. Our solution makes inspection of features on glossy or shiny surface significantly easier.

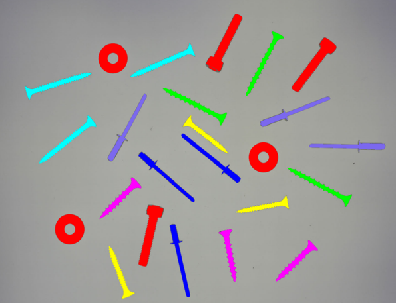

AI Machine Learning

Our system uses machine learning to automatically detect and identify parts based on training data. For example, it can distinguish various sizes and styles of wood screws and rivets by selecting optimal features during the training phase.

ROBOTICS & SYSTEM AUTOMATION

Robotics

Experienced with leading robotics like Universal Robots, FANUC, Mitsbishi, Doosan, Denso, Epson, and many others. In-depth knowledge of robots and cobots, allowing us to recommend the best solution for any application

Machine Design & Development

Full service design house for everything from simple tooling and fixtures to complete complex assembly lines and process automation. We make necessary adjustments to the design, ensuring a seamless integration into your operations and provide all necessary support and training to integrate the new systems or tools into your existing workflows.

R&D

We provide support when answers are unclear, with R&D experience spanning from manufacturing process development to laboratory research. We work closely with you to understand your goals, challenges, and vision, providing expert guidance to develop customized solutions that integrate seamlessly into your existing processes.

PLC CONTROLS

Custom Control Systems

Our advanced control systems are designed to make operation safer and more productive. Our team conducts rigorous tests to identify any potential issues, validate functionality, and fine-tune the system for maximum efficiency and reliability.

System Upgrades

When our clients need help navigating custom control systems, KTM Research can help. We have extensive experience developing control solutions for clients’ unique applications – whether that’s a full-integration control system for a new machine, or upgrading an existing system while preventing downtime.

Mobile Robotics (AMR/AGV)

KTM Research specializes in integrating and customizing traditional and collaborative robots, including AMRs, with vision guidance to automate labor-intensive tasks. Our expertise spans diverse applications, from data collection and navigation to complex material transport and mobile robots.

Turnkey Integration

We have successfully integrated cobots with AMRs to execute complex transport and offloading missions. For example, we developed a fully autonomous robotic system for a data center operator, combining an Oppent EVOcart AMR and a UR10 cobot to automate disk drive replacement.

Forklift & Unit Load AGVs

Designed for handling and transporting goods, these systems are commonly used in warehouses and manufacturing facilities. They efficiently move pallets between locations or transport individual units, such as containers or boxes, within production lines or distribution centers

Inspection AGVs

These AGVs are used for monitoring and inspecting specific areas at a facility, often equipped with sensors and cameras.

Ready to bring your vision to life?

Contact KTM Research today for innovative automation solutions tailored to your needs.

Let’s create the future, together!

About KTM

KTM Research is a small but dynamic firm specializing in custom integration services, including industrial machine vision, vision-guided robotics, and automation. As a small firm, we are able to implement solutions quickly and effectively. Our commitment to innovation and client satisfaction has positioned us as a standout in the industry, serving diverse sectors from consumer electronics to apparel manufacturing. At KTM Research, we simplify automation to deliver tangible results.

Founded in Portland in 2009, KTM Research was born out of the need to help business interface with academic researchers and labs at Oregon State University. Unlike other system integrators, we take a unique approach to business, driven by our willingness to innovate and explore new solutions. This mindset has enabled KTM to carve out a distinct position in the industry and stand apart from the competition.

Reach Us

Send us a message anytime!

Call Us

We're here to answer your calls!

Visit Us

3078 Schmidt Lane NE Hubbard, OR 97032

Copyright © 2024 KTM Indonesia